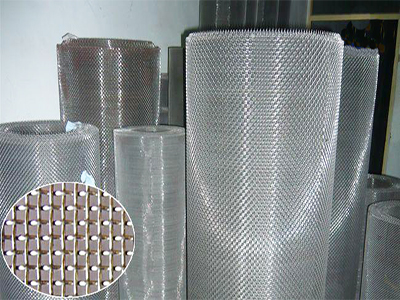

Titanium Mesh

Mesh Titanium:Titanium Mesh oo ay samaysay fiilooyinka Titanium Alloys, shirkadeena waxay ku midowday warshadda Mesh oo ballaarinaysa kala duwanaanta badeecada si ay u siligto alaabada mesh-ka iyo alaabada la sii farsameeyay.waxaan leenahay sanado badan oo waayo-aragnimo ah oo ku saabsan wax soo saarka mesh silig, iyo mesh titanium-ka ee la soo saaray ayaa leh sifooyinka waxqabadka shaandhaynta xasilloon oo wanaagsan.

• Noocyada:

→ Shabag toleedka cad → mesh tidcan oo tidcan

→ Shabakad tolmo oo horay loo curyaamiyay → Mesh Nederlandays tidde

• Tilmaamid: 1 mesh-100 mesh

Heerarka ASTM ayaa la raacayaa soo saarista meshes silig.Tilmaamaha mesh-ka la heli karo wuxuu u dhexeeyaa mid aad u culus ilaa mid aad u fiican.Mesh-ka ugu culus wuxuu ka samaysan yahay silig 8.0mm ah halka mesh-ka ugu fiican uu ka samaysan yahay silig 0.03mm leh 360mesh/inch.

Codsiyada:Mesh silig Titanium waxaa loo isticmaali karaa shaandhada heerkulka sare u adkaysta, dhismaha maraakiibta, wax soo saarka milatariga, filtarrada kiimikada, filtarrada farsamada, shabagyada gaashaanka korantada, filtarrada biyaha badda, heerkulka sare ee foornada kulaylka shabagyada, filtarrada saliidda, diyaarinta cuntada, sifaynta caafimaadka.

| Titanium Alloys Material Magaca Guud | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Alloys Kiimikada Halabuurka ♦

| Darajo | Halabuurka kiimikada, boqolkiiba miisaanka (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Qaybaha Kale Max.mid walba | Qaybaha Kale Max.wadarta guud | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum AlloyGuryaha Jirka ♦

| Darajo | Tilmaamaha jirka | |||||

| Xoog xajin Min | Xoog soo saar Ugu yaraan (0.2%, la dhimay) | Kordhinta 4D Ugu yaraan (%) | Dhimista Aagga Ugu yaraan (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |