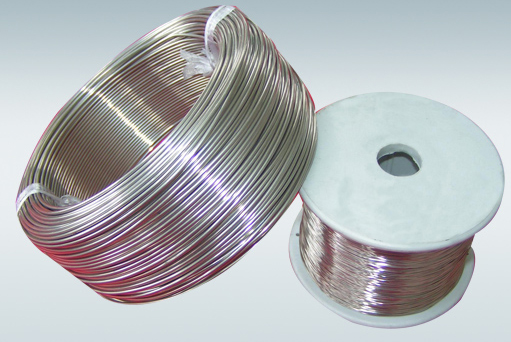

Titanium Wire

Titanium WireSiliga titanium-ka waxaa inta badan loo isticmaalaa alxanka, fareemada, qalliinka implants, qurxinta, qalab koronto laadlaad ah. Loo isticmaalo soo saarista budada titanium wareegsan.

Siligu isticmaal baararka titanium-ka ama Titanium slab tinto caaryada si loo farsameeyo, saamaynta jiidista awgeed, baararka titanium-ka waxa uu ku beddelmaa heer kul sare marka uu marayo daloolka caaryada.Qaybta iskutallaabtu waa la dhimay, dhererkuna wuu kordhay.Fidinta xaalad kulul waxay caawisaa in la baabi'iyo walbahaarka gudaha iyo hagaajinta caagagga fiilooyinka titanium.Waxay si wax ku ool ah u wanaajisaa saxnaanta fiilada titanium, iyo dusha sare, taas oo ku gaari karta waxqabad dhammaystiran oo wanaagsan.

• Qalabka Siliga TittaniumFasalka 1, Fasalka 2, Fasalka 5, Fasalka 5, Fasalka 7, Fasalka 9, Fasalka 11, Fasalka 12, Fasalka 16, Fasalka23 ect

Foomamka Xargaha: Ku dhufasho gariiradda, jar dhererka / toosan

• Dhexroorka: 0.05mm-8.0mm

• Xaaladaha:Xalka waa la tirtiray, rogid kulul, fidin

• Dusha sare:Cadan la soo qaado, dhalaalaysa oo dhalaalaysa, aysiidh la dhaqay, oksaydh madow

• Heerarka:ASTM B863, AWS A5.16, ASTM F67, ASTM F136 iwm

| Titanium Alloys Material Magaca Guud | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Halabuurka Kiimikada Fiilada Titanium ♦

| Darajo | Halabuurka kiimikada, boqolkiiba miisaanka (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Qaybaha Kale Max.mid walba | Qaybaha Kale Max.wadarta guud | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum Alloy WireGuryaha Jirka ♦

| Darajo | Tilmaamaha jirka | |||||

| Xoog xajin Min | Xoog soo saar Ugu yaraan (0.2%, la dhimay) | Kordhinta 4D Ugu yaraan (%) | Dhimista Aagga Ugu yaraan (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦♦♦ Titanium Alloy Materials Astaamaha: ♦♦♦

•Fasalka 1: Titanium saafi ah, xoog yar iyo ductility sare.

•Fasalka 2: titanium-ka saafiga ah ee inta badan la isticmaalo.Isku dhafka ugu fiican ee xoogga

•Fasalka 3: Titanium xoog sare leh, oo loo isticmaalo Matrix-plates ee qolofka iyo tuubada kuleyliyaha ku jira

•Fasalka 5: Alloy titanium-ka ugu warshadaysan.Xoog aad u sarreeya.caabbinta kulaylka sare.

•Fasalka 9: Xoog aad u sarreeya iyo iska caabbinta daxalka.

•Fasalka 12: Iska caabbinta kulaylka oo ka wanaagsan Titanium saafi ah.Codsiyada sida Fasalka 7 iyo Fasalka 11.

•Fasalka 23: Titanium-6Aluminum-4Vanadium ee codsiga maqaar-galaha qalliinka.