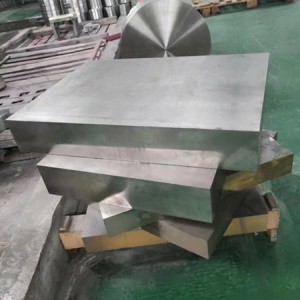

Warshada soosaarka isha mesh Titanium.Mesh silig Titanium, Mesh titanium caafimaad

Warshada soosaarka isha mesh Titanium.Mesh silig Titanium, Mesh titanium caafimaad,

Fasalka 2, Fasalka 5, Fasalka 11.Fasalka 12.Fasalka 16, Fasalka 23, Fasalka 7, Fasalka 9, Darajada, TA2, TAL, TC4,

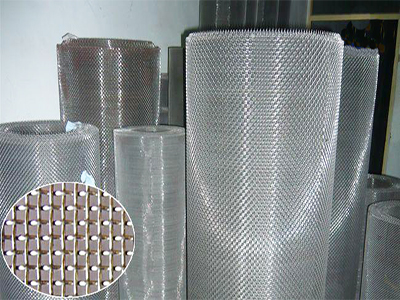

Mesh Titanium:Titanium Mesh oo ay samaysay fiilooyinka Titanium Alloys, shirkadeena waxay ku midowday warshadda Mesh oo ballaarinaysa kala duwanaanta badeecada si ay u siligto alaabada mesh-ka iyo alaabada la sii farsameeyay.waxaan leenahay sanado badan oo waayo-aragnimo ah oo ku saabsan wax soo saarka mesh silig, iyo mesh titanium-ka ee la soo saaray ayaa leh sifooyinka waxqabadka shaandhaynta xasilloon oo wanaagsan.

• Noocyada:

→ Shabag toleedka cad → mesh tidcan oo tidcan

→ Shabakad tolmo oo horay loo curyaamiyay → Mesh Nederlandays tidde

• Tilmaamid: 1 mesh-100 mesh

Heerarka ASTM ayaa la raacayaa soo saarista meshes silig.Tilmaamaha mesh-ka la heli karo wuxuu u dhexeeyaa mid aad u culus ilaa mid aad u fiican.Mesh-ka ugu culus wuxuu ka samaysan yahay silig 8.0mm ah halka mesh-ka ugu fiican uu ka samaysan yahay silig 0.03mm leh 360mesh/inch.

Codsiyada:Mesh silig Titanium waxaa loo isticmaali karaa shaandhada heerkulka sare u adkaysta, dhismaha maraakiibta, wax soo saarka milatariga, filtarrada kiimikada, filtarrada farsamada, shabagyada gaashaanka korantada, filtarrada biyaha badda, heerkulka sare ee foornada kulaylka shabagyada, filtarrada saliidda, diyaarinta cuntada, sifaynta caafimaadka.

| Titanium Alloys Material Magaca Guud | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Alloys Kiimikada Halabuurka ♦

| Darajo | Halabuurka kiimikada, boqolkiiba miisaanka (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Qaybaha Kale Max.mid walba | Qaybaha Kale Max.wadarta guud | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦ Titanum Alloy Physical Properties ♦

| Darajo | Tilmaamaha jirka | |||||

| Xoog xajin Min | Xoog soo saar Ugu yaraan (0.2%, la dhimay) | Kordhinta 4D Ugu yaraan (%) | Dhimista Aagga Ugu yaraan (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

Mesh Titanium waxaa inta badan loo isticmaalaa aashitada, xaaladaha deegaanka alkali baarista iyo sifeynta ama gaaska, sifeynta dareeraha ah iyo kala soocida warbaahinta kale.Waxaa jira afar hab oo tidmo cad, tolmo til, pre-crimp weave iyo Dutch weave.Saikang Metal Technology Co., Ltd. Waxaa ka go'an in ay macaamiisha siiso alaabo/adeegyo tayo leh