AMS ASME ASTM oo loogu talagalay inconel625 Alloy navigators

AMS ASME ASTM oo loogu talagalay inconel625 Alloy navigators,

625 Alloy, Inconel 625 Baars, Inconel 625 Ulaha, Inconel 625 xaashida, Inconel 625 saxan, Inconel 625 strip, Inconel 625 gariiradda,

Magacyada Ganacsiga Guud: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr.2.4856

Inconel Alloy 625 waa bir birlab ah, daxal iyo oxidation u adkaysta, daawaha nikkel-chromium.Awoodda sare ee Inconel 625 waa natiijada isku darka adag ee molybdenum iyo niobium ee saldhiga chromium nikkel ee daawaha.Inconel 625 waxa ay leedahay iska caabin aad u weyn oo ay u leedahay meelo badan oo daxalka ah oo aan caadi ahayn oo ay ku jiraan saamaynta kulaylka sare sida oksaydhka iyo carburization.Awoodeeda aadka u wanaagsan iyo adkaanta heerkulku waxay udhaxaysaa heerkul aad u sareeya ilaa 2000F (1093°C) waxay asal ahaan ka soo jeedaan saamaynta xalinta adag ee biraha refractory Columbium iyo molybdenum ee matrix nikkel-chromium.

Inconel 625 Halabuurka Kiimikada

| % | Ni | Cr | Fe | Mo | Nb+Ta | Co | C | Mn | Si | S | Al | Ti | P |

| Min. | 58.0 | 20.0 | - | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| Max. | - | 23.0 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.015 | 0.4 | 0.4 | 0.015 |

Inconel 625 Qalabka Jirka

| Cufnaanta | 8.4 g/cm³ |

| barta dhalaalaysa | 1290-1350 ℃

|

Inconel 625 Guryaha Makaanikada Caadiga ah

| Xaalada | Xoog xajin Rm N/mm² | Xoog soo saar Rp 0. 2N/mm² | Dheeraynta Sida% | adkaanta brinell HB |

| Daaweynta xalalka | 827 | 414 | 30 | ≤220 |

Inconel 625 Heerarka iyo Tilmaamaha

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3175-3.

UNS N06625, Workstoff 2.4856

| Silig | xaashi | Xarig | Usha | Dhuumaha | |

| AMS 5599, AMS 5666, AMS 5837, AMS 5979, ASTM B443 | ASTM B443 | AMS 5599, AMS 5979, ASTM B443 | ASTM B 446 SAE/AMS 5666, VdTÜV 499 | Dhuumaha aan Xumaan lahayn | Dhuumaha alxanka leh |

| ASTM B 444/B 829 & ASME SB 444/SB 829SAE/AMS 5581 | ASTM B704/B751 ASME SB704/SB 751ASTM B705/B 775 , ASME SB 705/SB 775 | ||||

Inconel 625 Alaabooyinka laga heli karo Sekonic Metals

Inconel 625 Baararka & Ulaha

Baararka wareega/ baararka fidsan/ baararka hex, Cabbirka 8.0mm-320mm, Loo isticmaalo boolal, xidhiyaal iyo qaybo kale oo dheeri ah

Inconel 625 silig alxanka

U keen silig alxanka ah iyo silig guga oo ah qaab gariirad iyo dherer la jaray.

Inconel 625 xaashi iyo saxan

Balac ilaa 1500mm iyo dhererka ilaa 6000mm, dhumucdiisuna waa 0.1mm ilaa 100mm.

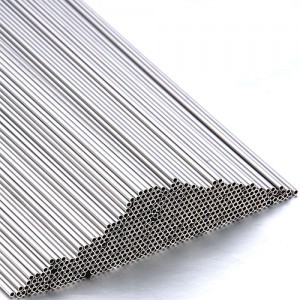

Inconel 625 tuubo aan kala go 'lahayn & tuubo alxan

Cabbirka jaangooyooyinka iyo cabbirka la habeeyey waxa lagu soo saari karaa annaga oo leh dulqaad yar

Inconel 625 strip & gariiradda

Xaalad jilicsan iyo xaalad adag oo leh dusha sare ee AB, ballac ilaa 1000mm

Inconel 625 xirayaasha

Alloy 625 waxaan ku siin karnaa boolal, lawska iyo xirmooyinka kale sida shuruudaha macaamiisha

Inconel 625 Astaamaha:

1.Awood sare oo gurguurta

2.Oxidation u adkaysta 1800°F

3.Daalka wanaagsan iska caabbinta

4.Weldability heer sare ah

5. Iska caabin aad u wanaagsan oo ku wajahan godadka chloride-ka iyo daxalka dillaaca

6.Immune to chloride ion stress daxalka dillaaca

7. U adkaysta biyaha badda ee ku jira xaaladaha qulqulaya iyo kuwa fadhiidka ah iyo kuwa wasakhaysan

Inconel 625 Goobta Codsiga:

•Nidaamyada marinnada diyaaradaha

•Nidaamyada qiiqa matoorka jet

•Nidaamyada riixista-reverser engine

•Gawaarida iyo kala goysyada ballaarinta

•Turbine sharoobada giraanta

•Xirmooyinka ololka

•Qaybaha biyaha badda

•Qalabka habka kiimikaad maaraynta asiidhyada isku dhafan labadaba oksaydheynta iyo dhimista.

Foomamka Alaabta Shirkaddayada

Baararka & Ulaha

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

Tube aan kala go 'lahayn & Tube alxan

Tuubooyinka Nikkel/Titanium Alloy Tubooyinka, U-qaloocinta/tuubada kulaylka

Bolt & nuts

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Xaashida & Taarikada

Hastelloy/Inconel/Incoloy/Cobalt/Tianium

Faleex & Fayl

Hastelloy/Inconel/invar/ jilicsan magnetic Alloys ect

Ilaha Heerkulka Sare

Inconel 718/Inconel x750/ Nimonic 80A

Silig & alxanka

Silig Alloy Cobalt, silig daawaha Nickel, Tianium Alloy silig

Flanges Alloy gaar ah

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Hanger Tube Saliid

Inconel x750/ Inconel 718 /Monel 400 ect

Alloys ku salaysan nickel

Qalabka alxanka

Alloys ku Salaysan Cobalt

Biraha Gaarka Ah

Alloys sax ah

Alloys Titanium

Ma rabtaa inaad wax badan ka barato ama aad hesho xigasho?

La xidhiidh

Waa maxay walxaha 625 ka samaysanAlwaax ku salaysan nikkel oo leh Ni – Cr – Mo.

Halabuurka kiimikada ee Alloy 625: Chromium (Cr) 20.0-23.0, Iron (Fe) <5.0, (Al) & lt;0.4, Silicon (Si)<0.50 manganese (Mn)< 0.50, Nickel (Ni)258, baaruud (S)< 0.015, Cobalt (Co)< 1.0, (Mo)8.0-10.0, Titanium (Ti)< 0.4, Fosfooraska (P) <0.015, (Nb) 3.15-4.15, Kaarboon (C) <0.01.

625 Alloy wuxuu leeyahay oxidation aad u fiican iyo iska caabin daxalka, xoog aad u fiican iyo adayg, iska caabin daal aad u fiican, qaabayn sare, iyo weldability aad u fiican.Waxay ilaalin kartaa xooggeeda iyo adkaanteeda meel kasta laga bilaabo heerkul hoose ilaa 2000F.Sababo la xiriira adkaynta degdega ah ee daawaynta 625, xaddi badan oo samaynta qabow ayaa laga yaabaa inay u baahdaan baabi'inta inta lagu jiro habka samaynta qabowga.Daawaha waxaa caadi ahaan loo isticmaalaa matoorada jet-ka iyo codsiyada kale ee hawada.