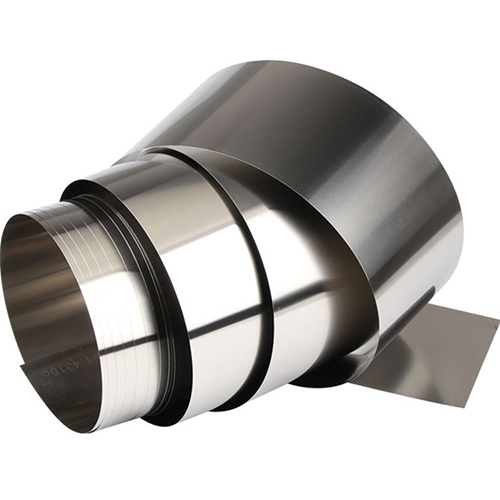

Xarigga Titanium, bireed titanium daahirnimo sare leh

Xarigga Titanium,bireed titanium daahirnimo sare,

Fasalka 2, Fasalka 5, Fasalka 7 iyo Fasalka 9, Darajada, bireed titanium daahirnimo sare, titanium caafimaad, Jidka Titanium, Tittanium Strip iyo Walxaha Foil: Titanium saafi ah (CP) iyo foil alloy Titanium,

• Tittanium Strip iyo Walxaha Foil: Titanium saafi ah (CP) iyo Titanium alloy foil, Fasalka 1,Fasalka 2, Fasalka 5, Fasalka 5,Fasalka 7 iyo Fasalka 9

Foomamka: Xariijimo keli ah, oo gariiradda ku jirta, ama dabaasha.Adeeg goynta waa la heli karaa

• Cabirka:Dhumucda: ≥0.01mm: 20 ~ 1000mm, Dhererka: Sida Codsiga

• Xaaladaha:Qabow duuban(Y)~Kulul duuban(R)~Lamariyey

• Heerarka:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 iwm

Codsiyada:Elektrooniga, kiimikooyinka, saacadaha, muraayadaha, dahabka, alaabta ciyaaraha, mishiinada, qalabka dahaadhka, qalabka deegaanka, golf iyo warshadaynta saxda ah.

| Titanium Alloys Material Magaca Guud | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Jidka Titaniumiyo Fool:Waxaan inta badan bixinnaa Strip titanium saafi ah oo Gr1, Gr2, Gr4 ah;For titanium alloy Foil, Waxaan inta badan ku siin Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 iyo darajooyin kale, Waxay la soo saaray oo ku salaysan saxan titanium la duubo qabow dheeraad ah;habka wax soo saarka ee xaashida titanium waa ka sii adag.Xakamaynta qallafsanaantu waxay si aad ah ugu adag tahay habka duubista.Taas waxaa lagu gooyn karaa cabbirro kala duwan iyadoo loo eegayo baahida macaamiisha, si weyn u gaabinaysa wakhtiga bixinta.

♦ Titanium Strip Halabuurka Kiimikada ♦

| Darajo | Halabuurka kiimikada, boqolkiiba miisaanka (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Qaybaha Kale Max.mid walba | Qaybaha Kale Max.wadarta guud | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦ Titanum Alloy Strip Sifooyin jidheed♦

| Darajo | Tilmaamaha jirka | |||||||

| Xoog xajin Min | Min xoogga wax-soo-saarka (0.2%, la dhimay) | Kordhinta 4D Ugu yaraan (%) | Dhimista Aagga Ugu yaraan (%) | Tijaabada laabta (Radius of Mandrel) | ||||

| ksi | MPa | ksi | MPa | 1.8mm Dhumucyada | 1.8-4.8mm Dhumucdiisuna tahay | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Titanium Alloy Materials Astaamaha: ♦ ♦ ♦

•Fasalka 1: Titanium saafi ah, xoog yar iyo ductility sare.

•Fasalka 2: titanium-ka saafiga ah ee inta badan la isticmaalo.Isku dhafka ugu fiican ee xoogga

•Fasalka 3: Titanium xoog sare leh, oo loo isticmaalo Matrix-plates ee qolofka iyo tuubada kuleyliyaha ku jira

•Fasalka 5: Alloy titanium-ka ugu warshadaysan.Xoog aad u sarreeya.caabbinta kulaylka sare.

•Fasalka 7: Iska caabbinta daxalka sare ee hoos u dhigista iyo jawiga oksaydhaynta.

•Fasalka 9: Xoog aad u sarreeya iyo iska caabbinta daxalka.

•Fasalka 12: Iska caabbinta kulaylka oo ka wanaagsan Titanium saafi ah.Codsiyada sida Fasalka 7 iyo Fasalka 11.

•Fasalka 23: Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for implant codsiga qalliinka.

Sekonic Metals Technology Co., Ltd waxay bixisaa saxan titanium, usha titanium, capillary titanium, boolal titanium, xidhe titanium, usha titanium, lawska titanium, qaybo qaabaysan… Waxay ka go'an tahay siinta macaamiisheena alaab / adeegyo tayo leh, haddii aad xiisaynayso noo alaabta iyo adeegyada fadlan nala soo xidhiidh, adiga oo sugi jawaabtaada